The GY-lDR310 series intelligent rotary drilling rig adopts a modular diesel-electric integrated travel drive system, a high.strength drilling system with a high drill rig, a high airfow slag discharge system, and a fully automatic intelligent controlsystem. It features wide operational coverage, high efficiency and reliability, safety and comfort, easy maintenance, andenergy conservation and environmental protection. It can meet the automated drilling requirements for blast holes in open.pit mines under harsh environments such as high cold and high altitude. This makes it an ideal equipment choice for digitaland inteligent mining construction needs, bringing significant economic and social benefits to mineral resourcedevelopment.

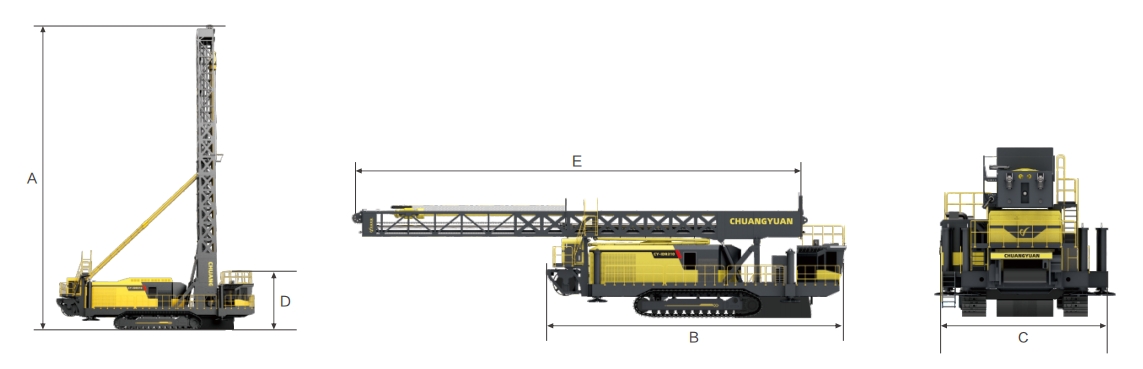

Overall Dimensions

| CY-IDR310 | A(m m) | B(mm) | C(mm) | D(mm) | E(mm) | Weight (t) |

| 29200 | 17400 | 7350 | 7370 | 28600 | 145 |

Performance Parameters

| Item | Unit | CY-IDR310 | |

| Drilling Method | / | / | Roller Bit |

| Power Type | / | / | Motor + Diesel Engine |

| Work environment | Altitude | m | 4000-5400 |

| Ambient Temperature | ℃ | -40℃-50℃ | |

| Working parameters | Drilling Diameter | mm | 250~310 |

| Single-rod Hole Depth | m | 19.6 | |

| Maximum Drilling Depth | m | 19.6/ 39.6 | |

| Drilling Angle | 90/60-90 | ||

| Rock Hardness | 1 | 14~120 | |

| Drill Rod Diameter | mm | 219、273 | |

| Air Compressor | Exhaust Pressure | bar | 5 |

| Air Volume | m³/min | 85 | |

| Power | kW | 355 | |

| Propulsion system | Drill Mast Length | m | 26 |

| Feed Stroke | m | 21.8 | |

| Feed Speed | m/min | 0-20 | |

| Thrust | kN | 480 | |

| Axial Pressure | kN | 520 | |

| Lifting Force | kN | 250 | |

| Hoisting Speed | m/min | 0-42 | |

| Rotary System | Speed | rpm | 0-145 |

| Torque | Nm | 0~35000 | |

| Power | kW | 220 | |

| Travel system | Walking Speed - Diesel | km/h | 0~1.7 |

| Walking Speed - Electric | km/h | 0-2.1 | |

| Climbing Ability | 14 | ||

| Ground Pressure | kPa | 100 | |

| Power System | Voltage | kV | June 10 |

| Substation Capacity | kVA | 500 | |

| Motor Power | kW | 220+90 | |

| Diesel Engine Power | kW | 221 | |

Functional Features

| Diesel-electric integrated walking drive system | High airfow slag discharge system |

| Addressing pain points such as heavy workload and low efficiency inthe relocation of electrically driven equipment due to cable wiring andguiding operations, this diesel-electric integrated travel drive systemeliminates the need for cable wiring and guiding during relocation. Itis suitable for long-distance relocation operations. When operating ona mature power supply platform, it utilizes electric drive for effcientenergy savings. | Equipped with a high airfow slag discharge system , ensuring high airreturn velocity under the design hole diameter. This effectivelyreduces secondary crushing and jamming issues caused by inadequateslag discharge.

|

| Safe and comfortable personnel operating environment | High drill rig robust drilling system |

| The spacious and comfortable pressurized cab is equipped withheating and air conditioning, intelligent control integrated seats, and aguided operating system, providing a safe and comfortable operatingenvironment. It features a remote control mode that frees personnelfrom vibration, noise, and hazardous environments, eliminating theneed for on-site manual operation. | Utilizing a high drill rig design, the single rod drilling depth reaches19.6m, meeting the maximum hole depth requirements for open-pitmetal mine blast holes. During continuous operation, there is no needto load and unload drill rods, allowing for rapid and accuratepositioning and guidance of the drill bit, significantly enhancingdrilling accuracy and efficiency.Utilizing a fully hydraulic distributed drive and load-sensitivehydraulic system, matched with a high-power drive system to achievepowerful drilling, capable of quickly penetrating various hard rockformations, significantly improving drilling speed. |

| Easy maintenance modular design | Fully automated operating system and intelligent perceptioncontrol system |

| The drilling downforce lifting system guide rails adopt a modularreplaceable design, signifcantly reducing the difficulty and cost oflater maintenance for the drill rig. Fully hydraulic distributed drivesolution, without mechanical transmission structures such as driveshafts, clutches, gearboxes, and transfer cases, resulting in low failurerates and simplified maintenance and replacement. With completemaintenance access channels, centralized refueling, centralizedlubrication, and fult self-diagnosis systems, equipment lifespan canbe significantly improved while reducing maintenance diffculty. | One-person control of multiple machines: Remote intelligent cockpitcan manage multiple drilling rigs, allowing operators to switchoperations between different equipment and areas as needed, therebyimproving equipment utilization and drilling hole managementefficiency. One-click autonomous operation: One-click automatic cable winding,automatic hole searching, automatic leveling, and automatic drilling toachieve autonomous and intelligent operation of multiple holes. |

Keywords:

CY-IDR310Blasthole Drilting Rig

Previous:

Next:

CY-IDR310Blasthole Drilting Rig

Contact Information

Category: