The CY-IDR250 series rotary Blasthole Drilling Rig is a new generation of intelligent drilling equipment developed specifically for perforation operations in open-pit mines under extremely cold conditions. The product is equipped with a diesel engine power system, diesel engine generator set, fully hydraulic travel and drilling system, high-airflow slag discharge system, and fully automatic intelligent control system. It features strong environmental adaptability, wide coverage of operating hole diameters, high efficiency and reliability, safety and comfort, as well as easy maintenance.

It can meet the automated drilling requirements for blast holes in open-pit mines under environmental temperatures ranging from -40°C to 50°C,F4-F20 Rock/ore firmness (firmness coefficient) from F4-F20 drilling diameter 200-270 mmdrilling angles of 60°-90°, and drilling depths of up to 52m. This makes it an ideal equipment choice for digital and intelligent mining construction needs, bringing

significant economic and social benefits to mineral resource development.

According to different application scenarios, there are options available with diesel engine power and electric motor power. The electric motor version can be equipped with a diesel power unit module to achieve electric drilling operations unand various conditions.

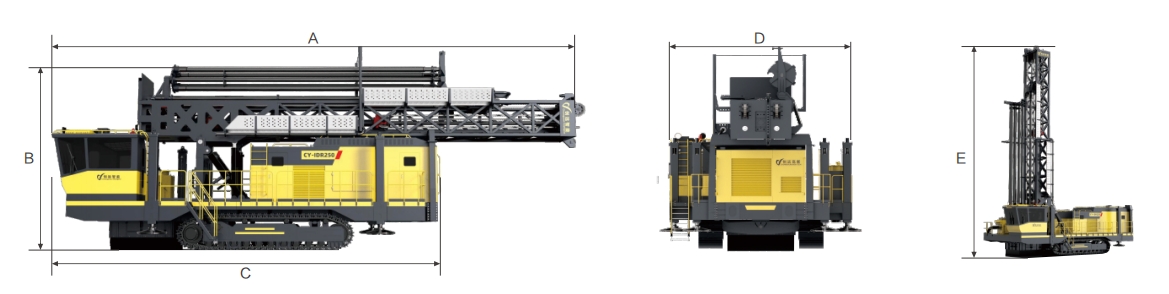

Dimensions

| CY-IDR250 | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | Weight (t) |

| 19200 | 7000 | 13800 | 6900 | 19500 | 115 |

Performance Parameters

| Item | Unit | CY-IDR250 | |

| Drilling Method | / | / | Roller bit |

| Power Type | / | / | Diesel Engine |

| Work environment | Altitude | m | <3500 |

| Ambient Temperature | ℃ | -40℃-50℃ | |

| Working parameters | Drilling Diameter | mm | 200-270 |

| Single Rod Drilling Depth | m | 9.4 | |

| Maximum Drilling Depth | m | 52.2 | |

| Drilling Angle | . | 60-90 | |

| Rock Hardness | / | 14~120 | |

| Drill Rod Length | m | 10.7 | |

| Drill Rod Storage Configuration | pcs | 4+1 | |

| Drill Rod Diameter | mm | 159-219 | |

| Air Compressor | Exhaust Pressure | bar | 8 |

| Air Volume | m³/min | 60 | |

| Power | kW | 355 | |

| Propulsion system | Mast Length | m | 15.3 |

| Feed Stroke | m | 12.84 | |

| Feed Speed | m/min | 0-27 | |

| Thrust | N | 350 | |

| Axial Pressure | kN | 380 | |

| Lifting Force | kN | 160 | |

| Lifting Speed | m/min | 0-48 | |

| Rotary System | Speed | rpm | 0-145 |

| Torque | Nm | 0-12800@110rpm | |

| Power | kW | 150 | |

| Travel system | Walking Speed | km/h | 0~1.42.3 |

| Gradeability | 14 | ||

| Power and Generation System | Ground Pressure | kPa | 100 |

| Generator Rated Voltage | V | 220 | |

| Generator Power | kVA | 50 | |

| Diesel Engine Power | kW | 670 | |

Optional Configuration

| Meets the requirements of diesel operation under extremely cold environmental temperatures | Full hydraulic walking and drilling system |

| The diesel-driven solution offers advantages such as independence from electrical power supply conditions, wide operational coverage, and convenient deployment. Key structural, sealing, and electrical components are designed to withstand low temperatures, ensuring reliable operation in cold environments. An independent diesel engine generator set can meet the system's electrical and heating needs in low-temperature environments. | Utilizing a fully hydraulic distributed drive and load-sensitive

|

| Fully automatic operation system and intelligent sensing control system | High-volume cuttings removal system |

| One-person control of multiple machines: Remote intelligent cockpitcan manage multiple drilling rigs, allowing operators to switchoperations between different equipment and areas as needed, therebyimproving equipment utilization and drilling hole managementefciency: One-clickautonomous operation: One-click automatic cable winding,automatic hole searching, automatic leveling, and automatic drilling toachieve autonomous and intelligent operation of multiple holes. | Equipped with a high airfow slag discharge system with an air volumeof 60m3/min and exhaust pressure of 0.8MPa, ensuring high airreturn velocity under the operating hole diameter. This effectivelyreduces secondary crushing and jamming issues caused by inadequateslag discharge.

|

| Easy-maintenance modular design | Safe and comfortable operating environment for personnel |

| The drilling downforce lifting system guide rails adopt a modularreplaceable design, significantly reducing the diffculty and cost oflater maintenance for the drill rig. The fully hydraulic distributeddrive solution ensures low failure rates and simplified maintenanceand replacement processes. | Addressing the heating requirements for extreme cold temperatures,equipped with an atomized fuel heater and insulated driver's cabin.ensuring high reliability and heating eficiency. It features a remotecontrol mode that frees personnel from vibration, noise, andhazardous environments, eliminating the need for on-site manualoperation. |

Keywords:

CY-IDR250Blasthole Drilling Rig

Previous:

CY-IDR250Blasthole Drilling Rig

Contact Information

Category: