Blog

2015/05/19

On April 29, 2015, our company participated in a public tender held by Xinjiang Ashele Copper Industry Zijin Mining Group Co., Ltd. in Xiamen, Fujian. Facing numerous competitors, our company won unanimous recognition from the expert evaluation group with its reasonable price, high-quality products and technology, and comprehensive service system. This also represents another affirmation of our company's comprehensive strength and technical level by Zijin Mining Group! We uphold our service commitment of "six-month return, one-year warranty, and lifetime service." We consider service a crucial part of our products and strictly adhere to the service system of "monthly visits and semi-annual inspections."

2015/04/15

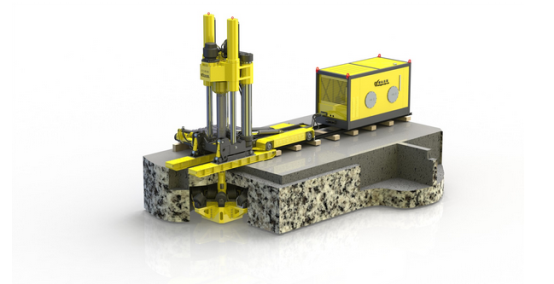

The extra-large aperture 3m ceiling drilling rig has entered the debugging phase

The CY-R series raise boring machines are developed by absorbing advanced design concepts from similar foreign products and fully considering the needs of domestic mining processes. They are intelligent reverse circulation drilling rigs with hard rock working capabilities, featuring high efficiency, safety, and ease of operation. They are essential digital equipment for safe raise boring in China's underground mines. Our newly developed CY-R120 raise boring machine, while meeting the intelligent requirements for hard rock operations, also boasts high efficiency, safety, and ease of operation, making it essential digital equipment for safe raise boring in China's underground mines. Its drilling diameter range covers 2.5m~3m, drilling

2014/12/19

Company Name Change Notification

Dear Valued Customer: Greetings! Due to the needs of company development, the name of "Changsha Chuangyuan High-tech Machinery Co., Ltd." was changed to "Hunan Chuangyuan High-tech Machinery Co., Ltd." on November 10, 2014. All business of the original company, "Changsha Chuangyuan High-tech Machinery Co., Ltd." will be continued by "Hunan Chuangyuan High-tech Machinery Co., Ltd." and all contracts signed by the original company remain valid. From now on, all internal and external documents, materials, invoices, accounts, and tax numbers will use the new company name. We sincerely apologize for any inconvenience caused by the change of company name.

2014/12/19

City Science and Technology Project Approval

My company has submitted a key project application for the "Research and Development of a New Type of Raise Borer for Hard Rock in Metal Mines", which has now been approved. The project involves the CY-R100, a new type of raise borer for hard rock in metal mines. This not only fills the gap in the domestic market for mechanized raise boring equipment for high-hardness rock in metal mines, but also improves the safety and reliability of raise boring construction in metal mines, increases efficiency, reduces construction costs and energy consumption. It is of great significance to improving the utilization rate of resources and the technical level of mining equipment, and is also in line with China's requirements for building an energy-saving society.

2014/12/01

The city's science and technology project successfully passed the defense

With the depletion of surface resources, resource extraction is gradually developing towards deeper levels. High-depth, large-diameter shafts have become essential for safe and efficient production, and traditional construction methods are no longer sufficient. To improve mining efficiency and ensure worker safety, the National Mine Safety Administration is planning to promote the mandatory safety construction standards for mechanized hole-making using shaft equipment, which has created a huge market space for shaft construction equipment, especially in the field of metal mine shaft construction. Our company's newly developed CY-R100 metal mine hard rock shaft drilling rig not only fills the gap in domestic metal mine high-hardness rock mechanical...

2014/05/27

The company has successfully reached a cooperation agreement with Anhui Tongguan Machinery.

The company successfully reached a cooperation development project for the CYT2.0 reverse well drilling rig with Anhui Tongguan Machinery Company. This project's reverse well drilling rig uses computer intelligent control and fully mechanized operation. Optimized design parameters allow for efficient operation in large-diameter hard rock. The technologies used have reached the advanced level of similar international products.