-

-

-

-

Service

-

Contact Us

Remote intelligent control of open-air top drive drilling rig

Remote intelligent control system for rotary drilling rigs

Drilling is the first and crucial step in the production process of all non-coal mines. The efficiency and quality of drilling significantly impact subsequent operations such as blasting, shovel loading, transportation, and crushing. Drawing on nearly three decades of rock drilling experience, Hunan Chuangyuan has developed the IM-ADS (auto drilling system) intelligent control system for drilling rigs. This system integrates automation technology, IoT, computer technology, big data analysis, and remote data transmission. It has been fully deployed in the market, enabling remote, automated, precise, and efficient drilling operations in mines.

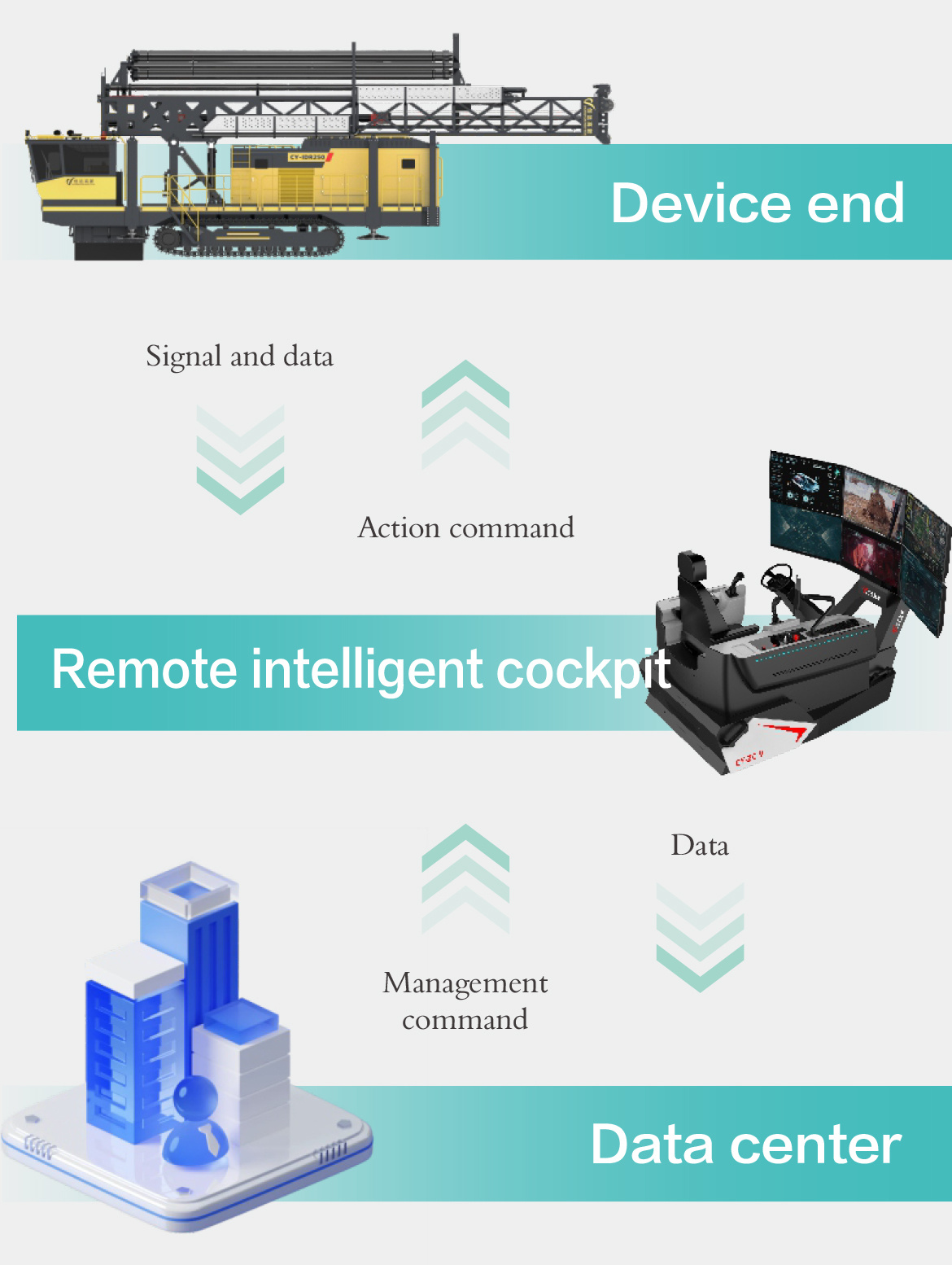

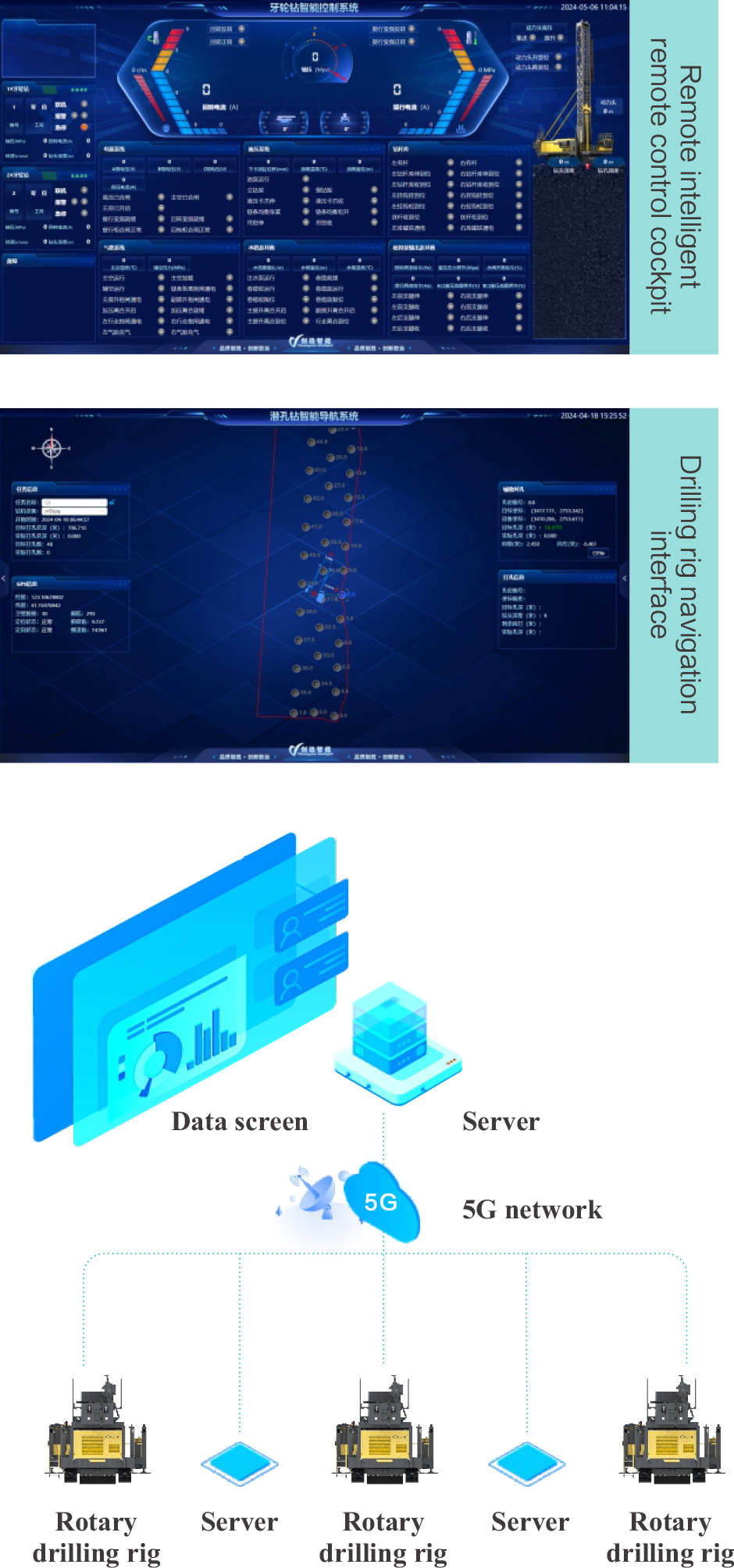

Remote intelligent remote control cockpit

High-altitude and low-temperature environment adaptation Designed for plateau conditions, the system adjusts to factors such as oxygen content, air pressure, air density, temperature, and ultraviolet radiation. It addresses issues such as low-temperature cold start, engine power loss, air compressor airflow loss, and heat dissipation. |

One-click autonomous operation Achieve automatic cable winding, automatic hole searching, automatic leveling, and automatic drilling with a single click. Enable multi-hole autonomous intelligent operations with automated hole searching, approaching the efficiency of manual operations through automation for individual equipment. |

Precise drilling navigation Utilizing Global Navigation Satellite System (GNSS), Inertial Measurement Unit (IMU), and coordinate transformation correction technology, it achieves real-time tracking and precise positioning of the drilling location and direction. |

|

Dual-server management system A new B/S architecture service management system that allows one person to control multiple machines. It employs remote/vehicle-side master-slave dual- server coordinated management, ensuring uninterrupted local intelligent operations even under network disruption. Once the network is restored, operational conditions and statistical data synchronize instantly. |

One person controls multiple machines Remote intelligent cockpit can connect and manage multiple drilling equipment, allowing operators to switch operations between different equipment and areas as needed, thereby improving equipment utilization and drilling hole management efficiency. |

Data analysis Equipped with equipment attendance analysis and optimized equipment scheduling functions, it provides guidance for blasting through operational data analysis. |

What can we help you find?

Address: Building C3, Huanchuang Enterprise Plaza, 2450 Yuelu Avenue West, Changsha, Hunan Province, P.R.C.

Copyright © 2025 Hunan Chuangyuan HIGH-TECH Machinery Co., Ltd.