-

-

-

-

Service

-

Contact Us

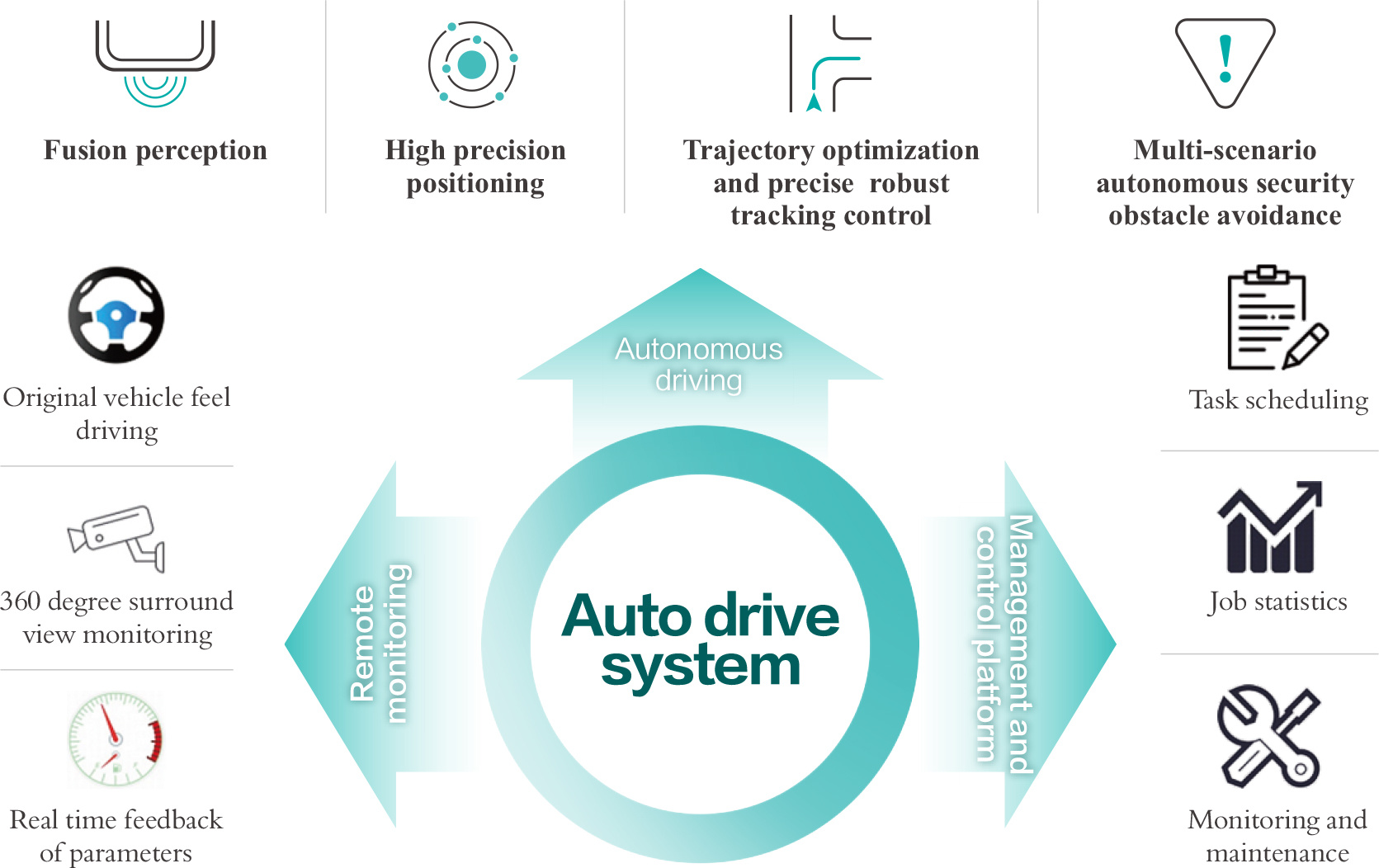

Auto drive system for outdoor vehicles

Open-pit vehicle transportation is the primary method for open-pit mining transport and a key factor influencing production. Hunan Chuangyuan utilizes multi-sensor fusion perception technology, high-precision RTK positioning technology, trajectory optimization with precise robust control technology, chassis wire-controlled drive technology, and artificial intelligence technology to independently develop an open-pit unmanned driving system. This system supports the intelligent construction of mines and achieves unmanned driving transport.

|

Suitable for all open-pit engineering vehicles |

Loader |

Bulldozer |

Sprinkler |

System Functions

Fusion perception Utilizing high-beam lidar, visual recognition cameras, and millimeter-wave radar for perception and fusion calculations, and the independently developed LDA noise reduction algorithms for dusty environments, the system achieves 360-degree non-blind-spot perception coverage of equipment. It is capable of real-time scanning and accurate perception of pedestrians, fixed facilities (signs, utility poles, etc.), and moving obstacles (large rocks, stockpiles, etc.) in light dust, light rain, light snow, and other harsh conditions. |

Safety During normal vehicle operation, the vehicle can utilize its perception system to detect and implement corresponding levels of obstacle avoidance strategies on infrastructure, static obstacles (large blocks, etc.), dynamic obstacles (pedestrians, oncoming vehicles). For instance, when encountering oncoming vehicles, the vehicle should yield to heavier vehicles; when pedestrians are detected, it should apply emergency braking if they approach too closely. If the vehicle approaches the edge of electronic fences (such as steps), it should initiate emergency braking to maintain a safe distance. In cases where autonomous or remote operation signals are lost, immediate deceleration should occur, followed by pulling over safely if conditions allow. |

|

High precision positioning With global satellite high-precision RTK positioning, the system achieves centimeter-level trajectory tracking, with fixed-point radar ranging positioning calibration, ensuring high-precision and stable parking. |

Precise and stable control Utilizing high-precision, real-time, and highly reliable wire- controlled steering and driving technology, the system can construct precise kinematic and dynamic model designs for real-time lateral and longitudinal tracking controllers, achieving precise and stable vehicle control. |

|

Trajectory optimization Based on the actual operating conditions of open-pit transportation equipment, we independently developed the DDAS (D-lateral safety distance, D-longitudinal safety distance, A-longitudinal baseline of transportation equipment, S-longitudinal baseline of loading equipment) route planning algorithm to achieve optimal positioning alignment between transportation equipment and loading equipment. |

Autonomous driving The vehicle is capable of automatic starting, accelerating, decelerating, braking, steering, and unloading along the planned route, enabling unmanned automatic cyclic transport operations. |

|

Remote takeover Remote multifunctional driving platform, including integrated original vehicle operation buttons, joysticks, and pedals on both sides of the driver's seat, faithfully replicates real cockpit operations. It features a front vehicle information screen displaying speed, RPM, oil pressure, and more, as well as a real-time 360-degree vehicle camera monitoring screen. Through vehicle ID matching, it allows for immediate intervention in any autonomous-driving-capable truck for manual driving intervention. |

Task scheduling According to the production plan, the system inputs each vehicle transport plan. The system will automatically execute production tasks. It allows for manual temporary reallocation where human authority supersedes automatic task allocation. |

What can we help you find?

Address: Building C3, Huanchuang Enterprise Plaza, 2450 Yuelu Avenue West, Changsha, Hunan Province, P.R.C.

Copyright © 2025 Hunan Chuangyuan HIGH-TECH Machinery Co., Ltd.