-

-

-

-

Service

-

Contact Us

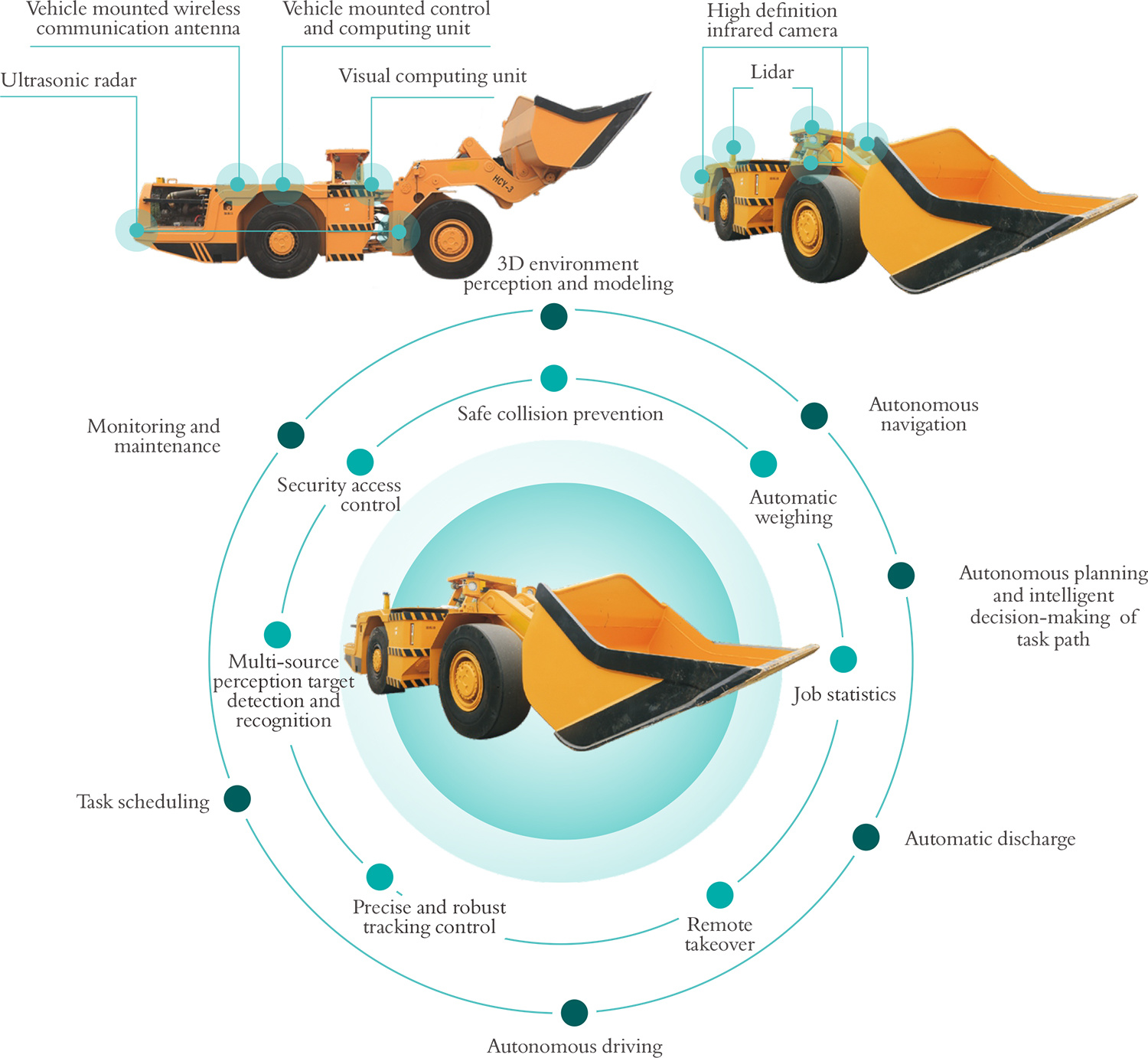

Underground vehicle autonomous driving system

The underground vehicle autonomous driving system utilizes advanced sensor technology, artificial intelligence, and intelligent control technology to achieve autonomous driving of underground vehicles. Advanced wireless communication technology, remote control, and visualization technology are used to achieve precise operation of the unloading of underground ore by loaders.

System Functions

3D environment perception and modeling The system is equipped with multi-beam lidar to scan and model the roadways in real-time, creating a visual map. It perceives the surroundings and tracks the vehicle's movement. |

Autonomous planning and intelligent decision- making of task path The system collects real-time environmental perception data, positioning data, and operational route data through a demonstration and teaching process to construct a topological map for scraper operation tasks. During autonomous driving, it integrates scraper position measurement data to initiate autonomous driving from any position within the operational area. It autonomously plans operational paths, navigates through intersections, and intelligently decides on actions such as stopping at unloading points. The controller achieves precise and stable vehicle control. |

|

Monitoring and maintenance Real-time fault diagnosis and visual audio-visual text prompts help quickly identify fault locations and statuses. Integrated maintenance reminders facilitate regular proactive maintenance and inspections, reducing equipment downtime and increasing effective operational time. |

Precise and robust tracking control The system employs high-precision, strong real-time, and highly reliable wire-controlled steering and drive-brake technology to construct precise motion and dynamic parameter models for the scraper. It designs real-time longitudinal and lateral tracking controllers to achieve high-precision and robust autonomous tracking control capabilities for the scraper. |

Remote takeover The remote multifunctional driving platform, including integrated original vehicle operation buttons, joysticks, and pedals on the left and right armrests of the driver's seat, recreates the operation of a real driving cabin. A full LCD display screen is used to show real-time underground vehicle positioning information, driving speed, grid information, slope angles, etc. It also displays driving maps, paths, and multiple-angle real-time images from monitoring cameras. Operators can take over control of underground vehicles at any time. |

Job statistics Actual operational data statistics automatically track ore production quantities, generating daily, weekly, and monthly reports for production reference and decision-making. |

Multi-source perception target detection and recognition The system uses lidar and stereo cameras to perceive real-time environmental data, and employs image recognition technology and neural network algorithms to achieve semantic segmentation of scenes, and real-time identification of drivable areas and wall edge information within roadways.

|

Safety During automated driving, the vehicle will temporarily stop under the following conditions: detection of vehicles, personnel, or large falling rocks ahead by lidar or visual cameras, pressing the emergency stop button, loss of signal connection for the scraper, or intrusion of equipment or personnel into the safety grating. |

What can we help you find?

Address: Building C3, Huanchuang Enterprise Plaza, 2450 Yuelu Avenue West, Changsha, Hunan Province, P.R.C.

Copyright © 2025 Hunan Chuangyuan HIGH-TECH Machinery Co., Ltd.