-

-

-

-

Service

-

Contact Us

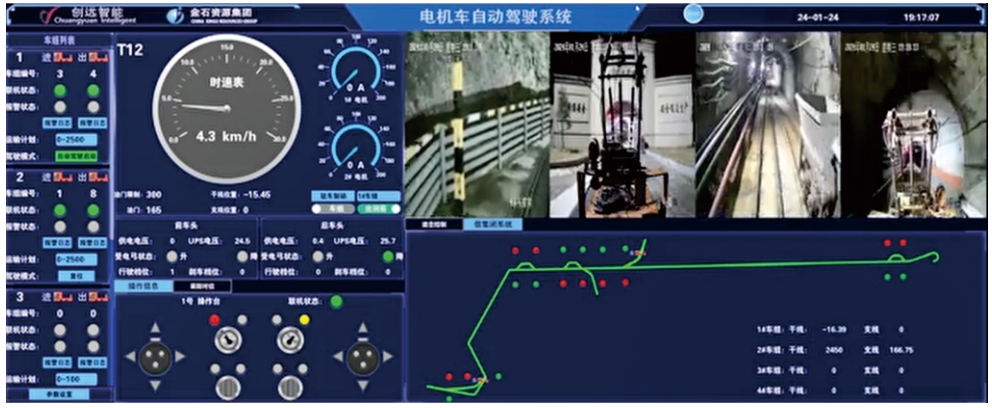

Electric locomotive auto drive system

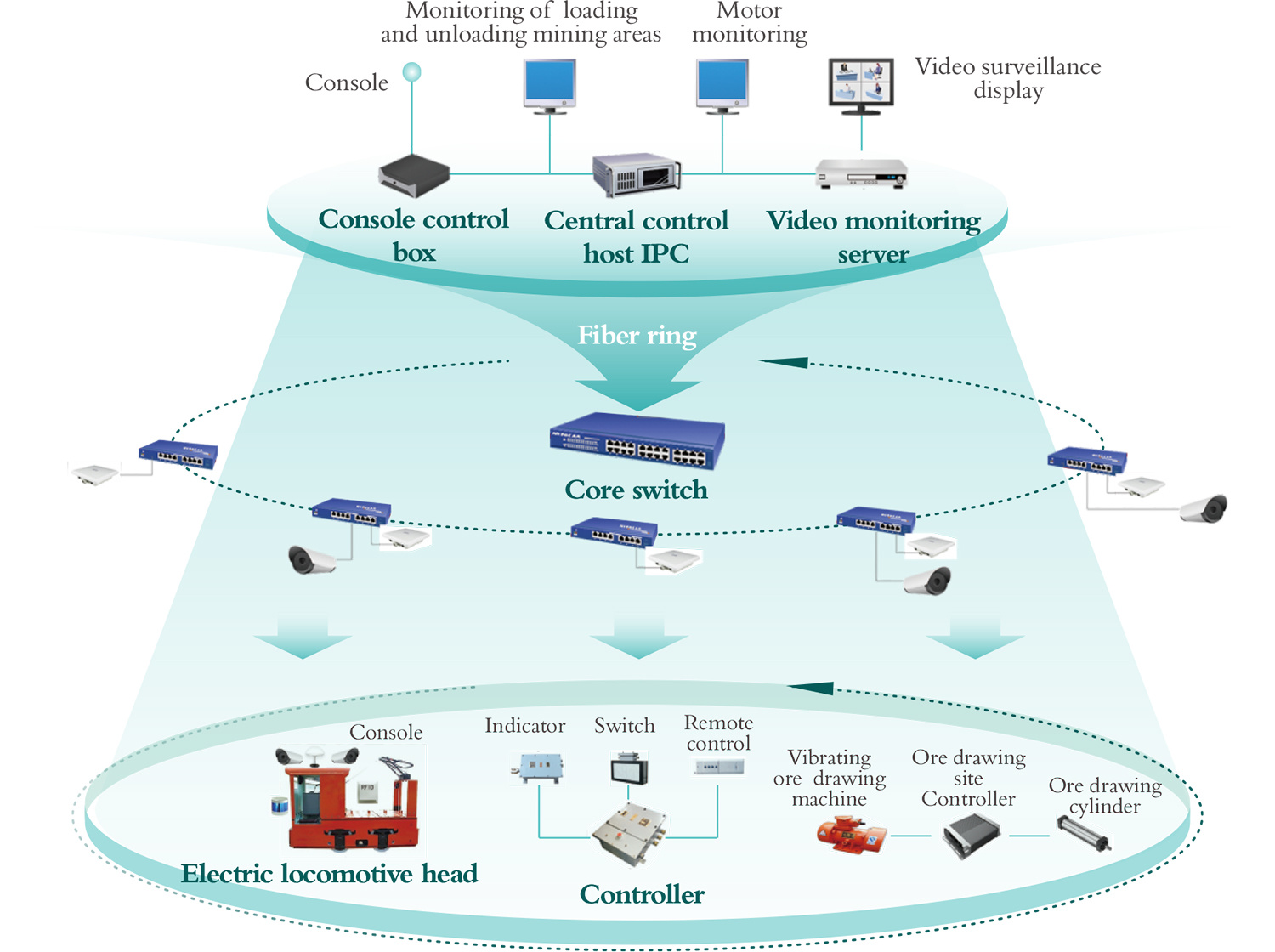

The auto drive system for mining rail equipment is based on AI technology, designed for mining transportation vehicles such as mining locomotives and monorail cranes in low-light and potentially explosive environments. The system utilizes high-speed wireless communication, fiber optic ring networks, or 5G communication technology as transmission platforms. It relies on a self-developed mining transport monitoring system for safety assurance, employing precise positioning technology for underground locomotives, GIS technology, machine vision technology, UWB centimeter-level positioning technology, and locomotive security emergency support technology. It also integrates an innovative locomotive intelligent driving algorithm to achieve unmanned driving operations throughout the entire process of loading, transporting, and unloading ore and materials.

System Functions

Material level detection technology for chutes and ore drawing pits The system utilizes our specially developed X-band radar combined with single- beam laser technology to automatically detect the ore level inside the chute. On one hand, it controls the ore drawing from the chute, and on the other hand, it directs the locomotive for ore loading. The system automatically detects and schedules the ore drawing machine to maintain a certain height of ore level to ensure the safety of the crushing station below it. |

Unloading station material level and ore jamming monitoring The material level sensor continuously monitors the material level in the unloading station. As the vehicle approaches the unloading station, the system predicts whether all the material in the vehicle can be completely unloaded into the unloading station. It then controls the locomotive accordingly. If it detects that large pieces of material have not been unloaded, causing the bottom plate of the ore car to remain open, the system immediately issues an alarm and automatically stops the vehicle. It waits for personnel to handle the abnormal situation. |

|

Automatic ore loading Automatic ore loading technology is a critical aspect of locomotive autonomous operation, whether in underground or surface control centers. It achieves automatic ore loading without the need for human intervention, involving the comprehensive application of multiple technologies. These include precise positioning of the railcars, control of the ore drawing machine, and detection of the ore level in the loading railcars. |

Locomotive unmanned operation control The vehicle mounted controller receives instructions from the remote control center system via the network. It automatically adjusts locomotive operations such as starting, accelerating, maintaining speed, decelerating with brake control, stopping, and raising/lowering the pantograph. It then feeds back the execution results to the ground control center. |

Autonomous locomotive speed cruising Based on cruising principles, a vehicle variable speed cruising model (adaptive cruising model) is established. According to the driving instructions issued by the production optimization scheduling software model, and considering the objective distribution conditions of the track/road, such as straight and curved sections ahead, and the need for avoidance, the system achieves adaptive track following and scheduling instructions. It autonomously adjusts the driving speed to facilitate autonomous operation throughout the entire process of loading ore, traveling, and unloading ore. This capability is central to controlling multiple locomotives with one operator.

|

|

What can we help you find?

Address: Building C3, Huanchuang Enterprise Plaza, 2450 Yuelu Avenue West, Changsha, Hunan Province, P.R.C.

Copyright © 2025 Hunan Chuangyuan HIGH-TECH Machinery Co., Ltd.